Navigating Warehouse Space Challenges in 2024: Unlocking the Value of Brownfield Warehouses

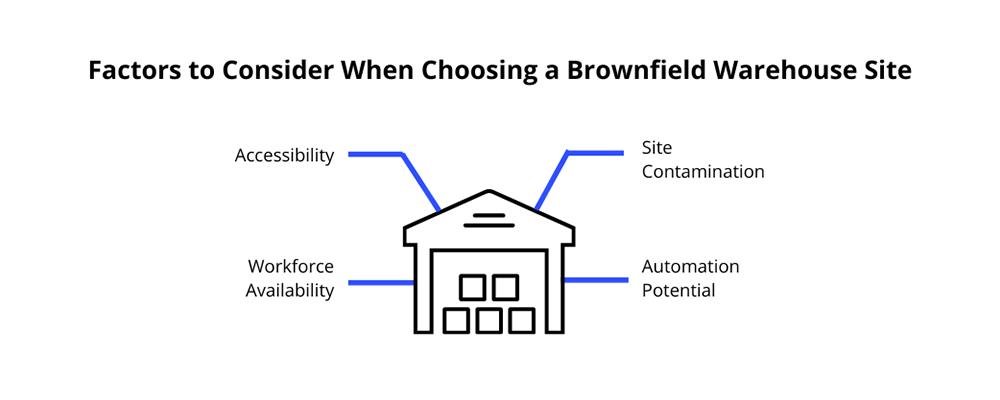

As the demand for warehousing solutions continues to evolve, embracing brownfield initiatives emerges as a strategic imperative for companies looking for adaptable, cost-effective, and efficiency-driving warehouse solutions. by Bart De Muynck, Supply Chain Thought Leader and Former Gartner Analyst The 2024 supply chain landscape is rapidly seeing a shift in the warehouse sector. During the pandemic, we saw a huge investment push for greenfield construction for new warehousing in order to keep up with the surge of inventory coming into the United States. That trend has slowed down, and with it, so has the construction of new warehouse space. With vacancy rates decreasing and less appetite for large greenfield investments, companies are turning to retrofitting current warehouses through brownfield projects to accommodate current consumer behavior and industry developments. In 2023, 25% fewer warehouses were built in the US, according to research firm Interact Analysis. With lower vacancy rates and greenfield investment projects costing $100 million or more, companies have to explore brownfield projects to minimize development costs, increase efficiency in their operations, and improve the performance of existing facilities. A brownfield investment does have more limitations than a greenfield investment when it comes to the layout of the building and existing equipment. This limits what new inventory can be held there and what new material handling equipment can be employed. The location and size of the facility may also limit the ability of a company to meet current needs. Taking all of that into account, the benefits of a brownfield project still outweigh its challenges. Starting with lower development costs, it’s easy to see how redeveloping a brownfield site is cheaper than building a brand new one. Infrastructure, such as roads, utilities and loading docks, is already in place at the warehouse and surrounding areas. Chances are, architects don’t have to be called or permits applied for, as there is no need for additional construction. Development costs alone are a big factor in companies choosing to invest in a brownfield warehouse, especially in this uncertain economy. When analyzing which facilities make good candidates for brownfield projects, there are a few factors to consider. In terms of accessibility, proximity to transportation routes, such as major highways or railway lines, is ideal, as this allows for more efficient movement of goods in and out of the warehouse. Access to populated centers, such as urban areas, can be an advantage for faster delivery services. If there is a possibility of site contamination, the cleanup process should be treatable within reasonable budget constraints. The site location should also have access to a workforce with the aligned skills needed within the warehouse, and enhance operations with automation to fill the labor gap and streamline operations. Companies, especially in the retail sector with underperforming stores, can convert former stores into e-commerce fulfillment centers, turning them into “dark stores.” This benefits retailers, as dark stores have ample space and are located near populated areas, such as shopping malls. Multi-tenant warehousing facilities are also on the rise as companies use dark stores to section off smaller storage spaces for multiple tenants to maximize storage space. This is called micro-fulfillment or market fulfillment and creates small footprints for companies in the warehousing ecosystem, growing rapidly in popularity among businesses needing smaller storage spaces. Once a site has been identified as a good brownfield warehouse, it’s important to turn focus to the software to provide orchestration and automation to boost efficiency and supplement the labor gap. According to Gartner®, by 2028, 80% of warehouses and distribution centers will deploy some form of warehouse automation. Brownfield sites are better suited to smaller-point solutions that automate particular workflows, such as mobile robots. Since the share of brownfield sites has now increased, the share of point solutions (relative to end-to-end solutions) has also increased. Automation technologies, such as automated storage and retrieval systems (AS/RS), can be integrated into brownfield warehouses to optimize storage density within a smaller footprint. This allows for maximizing usable space, especially in situations where the overall warehouse size is limited. When it comes to integrating technology into a brownfield site, none is more important than the warehouse execution system (WES) software within those four walls. Broadly speaking, a WES helps maximize efficiency by orchestrating and optimizing warehouse operations in real-time. A WES serves as the brain behind the brownfield operation, boosting efficiency and throughput while bridging the gap between floor operations and enterprise-level decision-making. By leveraging advanced algorithms and automation capabilities, WES optimizes order fulfillment processes, minimizes idle time, maximizes resource utilization, and optimizes old and new automation. This is particularly crucial in smaller, space-constrained brownfield facilities, where every square foot counts. A knowledgeable WES partner, such as FORTNA, works with you to determine inventory, throughput, service level agreements (SLA) and requirements, in addition to other factors. The initial stage of partnering with a WES provider is a crucial one. Many situations have to be taken into account to accommodate customer demand as well as allow for adjustments from disruptions. “FORTNA runs advanced algorithms to simulate different types of equipment and technology incorporated into a brownfield project. We analyze a wealth of data to predict how the technology and equipment will succeed in a brownfield environment. We also provide a digital twin to audit the equipment already in action to ensure the system is operating properly as shown previously in the simulation,” stated Jeff Cashman, Senior Vice President, Corporate Development. A WES partner orchestrates automation within a brownfield warehouse by seamlessly integrating with automation technologies, such as mobile robots and robotic arms. This allows the WES to optimize workflows and reduce manual intervention. Picking strategies are also optimized based on real-time demand and inventory levels, ensuring optimal resource allocation and minimizing delays. In micro-warehousing and dark stores, where space optimization is paramount, automation enables vertical storage and seamless order fulfillment. A WES allows companies to make operating decisions based on current conditions within the distribution environment. It provides more prescriptive and execution-focused benefits compared to a warehouse management system (WMS). “We know exactly what’s going on at a point in time, in real-time, to make the changes or not. Through our WES, we know that we have to do something different based on a robot going down, a sorter going down, or some mechanical issue or person that’s caused a problem in that flow or in that lane. All of that is seen through our WES, full visibility in real-time,” added Cashman. The shift towards brownfield warehouses requires adaptable solutions, such as WES, to optimize existing infrastructure. No other technology system can achieve such orchestration levels in a brownfield warehouse as a WES can. A WES also facilitates the quick deployment of new technologies to enhance productivity and return on investment (ROI) for companies. An added bonus of redeveloping brownfields is the sustainability aspect. By reusing existing land, companies are not utilizing additional land and resources. Brownfield warehouses are energy-efficient, as automation technologies can incorporate energy-saving designs to reduce consumption. Improved accuracy in inventory management and order fulfillment through warehouse orchestration minimizes waste and reduces the environmental impact of excess inventory. In terms of transportation waste, automated and WES-supported brownfield warehouses can optimize routes and schedules, reducing fuel consumption and emissions. As the demand for warehousing solutions continues to evolve, embracing brownfield initiatives emerges as a strategic imperative for companies looking for adaptable, cost-effective, and efficiency-driving warehouse solutions. Brownfield warehouses, with their potential for flexibility and customization, emerge as an optimal choice for companies aiming to align their warehousing strategies with evolving inventory management goals. As we move forward, brownfield warehouses will undoubtedly play a crucial role in shaping the future of warehousing and logistics, providing a blueprint for agile, resilient and sustainable business operations. With proper planning and execution, brownfield warehouses can be a significant source of much-needed storage solutions in the US in 2024 and beyond. Bart De Muynck is a Supply Chain industry thought leader with more than 30 years of experience working for logistics companies, manufacturers, technology companies, and consulting companies, as well as an analyst working for a leading research & advisory company. Bart De Muynck has made significant contributions to the industry through his research and expertise in supply chain technology and visibility solutions. Bart De Muynck’s impact on the industry lies in his efforts to drive digital transformation and improve supply chain efficiency. By promoting the use of data and analytics, he has helped organizations optimize their logistics processes, enhance customer experiences, and reduce costs. Additionally, his research and thought leadership have contributed to the overall understanding of supply chain best practices and emerging trends.Overall Supply Chain Trends

The Rise of Brownfield Warehouses

The Increasing Role of Technology

How a WES Strengthens Brownfield Warehouses

Sustainability

Takeaways